Boulter Camray 3 Oil Boiler Manual

I have a Boulter Camray 5 oil fired combi boiler. Every 48 hours or so it trips then restarts first time every time the trip is re-set. My heating engineer initially suggested this was caused by a faulty central heating pump, then suggested it may be the solenoid, both have been replaced. Jan 08, 2017 Does anyone have the manual available for a Boulter Camray 3 oil boiler at all? Have tried a few links and I am getting nowhere. Am a member on oil techs forum but can not get past the intro stage on there to see if it is in there. Any help would be appreciated.

View and Download Boulter Camray 5 installation & maintenance manual online. Boulter Camray 5 Oil Fired Boilers. Camray 5 Boiler pdf manual download. Camray 3 Oil Boiler Manual. Shonan junai gumi scan ita download. Discussion in 'Oil and Solid Fuel Forum' started by jackplumb. Online Boiler Manuals Download Boulter Camray 3 Boiler Manual. Mar 25, 2012 - On 08:08, Tim wrote: Simon wrote: anyone? TIA This any good?

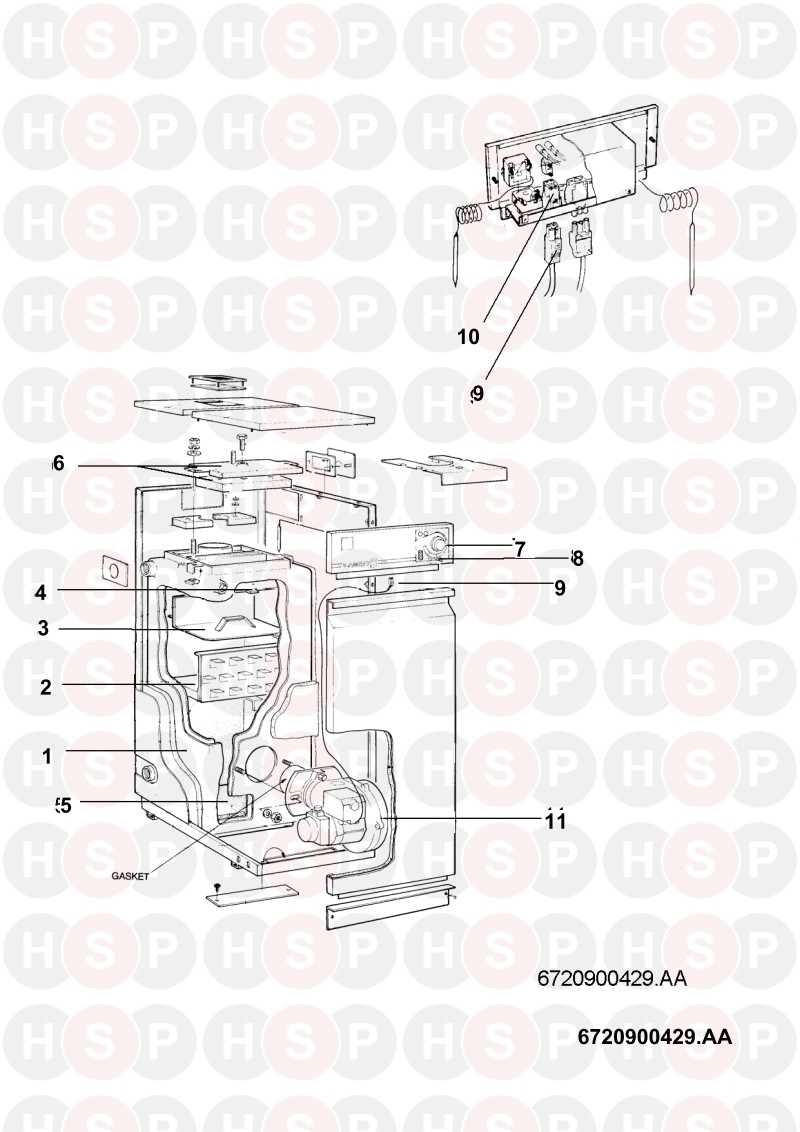

Boulter Camry 3 Oil Boiler Manual Diagram

Advertisement

Related Manuals for Boulter CAMRAY 5 COMBI

Summary of Contents for Boulter CAMRAY 5 COMBI

- Page 1 Page 1 of 77 COMBI OPERATING, INSTALLATION & MAINTENANCE MANUAL CAMRAY 5 COMBI Oil Fired Boilers (55, 70A & 90A) Manual Part No PL50000 Issue No. 5 Date of Issue February 2003 HEALTH AND SAFETY INFORMATION FOR THE INSTALLER AND SERVICE ENGINEER.

- Page 2 30 White House Road, Ipswich IP1 5JA Telephone: (01473) 241555 Boulter Boilers Fax: (01473) 241321 A subsidiary of Buderus Heiztechnik GmbH Due to a policy of continual development reserves the right to alter or amend the design of its products without prior notice.

- Page 3 Page 3 of 77 1:1 Introduction 1:2 Useful Information 1:3 Important Safety Notes 1:4 Connections 1:5 Installation and Commissioning 1:6 Boiler Control Panel 1:7 Operating Features and Instructions 1:8 Maintenance 1:9 Failure to Start SECTION 2 - INTRODUCTION 2:1 Introduction 2:2 Hydraulic Circuits 2:3 Flue Options 2:4 Commissioning..

- Page 4 CAMRAY 5 COMBI PAGE 1 1:1 INTRODUCTION Thank you for choosing the Camray Combi manufactured in the UK by Boulter Buderus who are renowned oil-firing specialists. To obtain the best possible performance and trouble free operation from your Boiler, it is important that you read section 1 of this manual carefully.

- Page 5 Information can be found on appliance data label located inside the left hand side panel of the casing. Also on the front cover of your installation manual. CAMRAY 5 COMBI PAGE 2 1:3 IMPORTANT SAFETY NOTES To obtain the best possible performance and trouble free operation from your Boiler, it is important that you read these instructions carefully.

- Page 6 O.F.T.E.C.* registered engineer. It is the responsibility of the installer to ensure that the Boiler is commissioned. If an engineer is not known, Boulter Buderus will be pleased to provide details of a commissioning and servicing engineer from their register.

- Page 7 If this temperature is likely to cause nuisance or discomfort your installer should be able to advise on a suitable temperature blending valve. CAMRAY 5 COMBI PAGE 3 1:6 BOILER CONTROL PANEL Boiler Control Panel (see 1.

- Page 8 (see 1b). lf the burner locks out again wait 3 minutes and repeat the operation again. If the problem occurs again, turn the boiler off and consult your installer. CAMRAY 5 COMBI PAGE 4 file://D:PL50000PL50000.htm 14/04/2005..

- Page 9 Page 9 of 77 Fig. 1b Lockout Reset 1:7 OPERATING FEATURES AND INSTRUCTIONS 1:7.1 How does your boiler work? Hot Water 1 If the Programmer is set for Hot Water only or the Summer/Winter switch is set to Summer :- a) The boiler will operate until the hot water tank reaches the temperature you have set on the Hot Water Tank Thermostat.

- Page 10 Control Panel, or the programmer switch to the OFF position on the optional programmer. 1:7.3 Sealed System Central Heating Your Camray 5 COMBI Boiler may only be used on a SEALED SYSTEM. It is important that the correct operating system pressure is maintained. If the System Pressure Gauge, in the Control Panel, should indicate low pressure i.e.

- Page 11 CAMRAY Boilers offer greater freedom to select the most suitable position for siting and the opportunity to install the boiler in a suitable outbuilding if required. All models are supplied for connection to a conventional chimney or any of the available Camray 5 Combi Balanced Flue options.

- Page 12 Page 12 of 77 Fig. 2a Schematic Diagram Camray 5 Combi CAMRAY 5 COMBI PAGE 7 2:2 HYDRAULIC CIRCUITS file://D:PL50000PL50000.htm 14/04/2005..

- Page 13 Page 13 of 77 Fig. 2b Hydraulic Circuits 2:3 FLUE OPTIONS CAMRAY Boilers are designed to operate with high efficiency, clean combustion and low noise level. They offer unique versatility and can be used in the following modes: 1. Low level rear outlet balanced flue. 2.

- Page 14 Non compliance with the above will invalidate the Guarantee. 3:1 LIQUID FUELS The Camray 5 COMBI Boiler will burn liquid fuels complying with BS2869 Part 2 1988 Class C2 specified in the Code of Practice for Oil Firing BS5410 Part 1.

- Page 15 Page 15 of 77 Heat Input (Full load based on Net efficiency of 91%) Heat Output (Full load) Maximum Boiler working pressure 3 bar Class 2 - 30.6m water head Minimum return water temperature Maximum side panel temperature <35 C above room temperature Conventional flue - Minimum flue draught 0.09mbar (0.035'w.g.) Conventional flue - Maximum flue draught..

- Page 16 22.5kW 17.7kW 26.4kW 20.5kW 16.1kW CAMRAY 5 COMBI PAGE 9 3:5 DIMENSIONS 3:6 TUNDISH POSITION A Tundish must be fitted to provide a visual indication of water flowing from the Pressure Relief Valve of the Boiler. Installation of the Tundish must be located in a position clearly visible to the householder i.e. to comply with Part G of the Building Regulations -typically as fig.3.b..

- Page 17 Page 17 of 77 Fig. 3b Tundish Position CAMRAY 5 COMBI PAGE 10 3:7 COMMISSIONING DATA 3:7.1 Class C2 Kerosene Oil Model Output Riello Danfoss Pump Fuel % Smoke Flue Exit Boiler Test Burner Nozzle Pressure Rate Point Temp Temp..

- Page 18 Page 18 of 77 CAMRAY 5 COMBI PAGE 11 3:8 PERFORMANCE DATA Fig. 3c Performance Graph Fig. 3d Pump Head Graph CAMRAY 5 COMBI PAGE 12 4:1 STANDARDS& REGULATIONS The installation of the Boiler must comply with latest edition of : BS 5410 Oil Installations Pt 1 under 44kW;..

- Page 19 4. The Camray 5 Combi Boiler model is serviced from the front and top. A space of 450mm (18 ) in front and above the Boiler should be available. (On CF a 15mm gap at the rear must be provided for air entry).

- Page 20 6. Boiler installation in bedrooms or living rooms should be avoided if possible. 4:4 THE HEARTH The Camray 5 Combi has a Hearth Temperature of less than 85 C. The Boiler require a level hearth on which to stand which should comply with the Building Regulations.

- Page 21 Page 21 of 77 Pressure 14.5 21.8 Expansion Vessel size supplied Total water content of system including 40 litre tank using expansion vessel supplied. 12 litres litres gallons 16.5 For systems having a larger capacity multiply the total system capacity by the factor o obtain the total minimum 0.08 0.11 0.16..

- Page 22 Boulter have taken particular care in the design of this Boiler to minimise this (hard water) effect but, strongly recommend that in areas where water temporary hardness (alkalinity) in excess of 150 mg/l is likely to be encountered, a water conditioner of the chemical dosing type is fitted.

- Page 23 The Boilers Pressure Relief outlet pipe is 15mm. The installations connecting pipe work to a suitable Tundish must be in accordance with G3 Building Regulations (see Fig. 3b). CAMRAY 5 COMBI PAGE 16 4:9 THE CHIMNEY - (FLUE dia 4') CONVENTIONAL CHIMNEY INSTALLATION ONLY. VERY IMPORTANT All Camray 5 boilers are supplied in Balanced Flue Form.

- Page 24 When the Boiler is installed in a basement or low level boiler house where air can enter only from high level, the incoming air supply for Combustion and Ventilation should be ducted to low level. A high level outlet should be provided for ventilation. CAMRAY 5 COMBI PAGE 17 4:11 OIL STORAGE file://D:PL50000PL50000.htm..

- Page 25 50mm thick garden slabs or a concrete base. As there is only one tapped outlet they are more suited to single pipe feed as gravity supply or with a Boulter 3K Oil Loop Deaerator where suction lift is required.

- Page 26 To prevent damage to the capillary always pass the sensor through the blind grommet (supplied), it will be necessary to cut across the diaphragm. *Remote Acting Fire Valves are available from Boulter, through your merchant or installer e.g. Ref: Operating..

- Page 27 Page 27 of 77 Boulter 3K Deaerators are available as an optional extra from your merchant (Part No. BS 03060). 4:12.6 Water Separator Oil Filter For changeover applications, the use of a Water Separator Oil Filter, available from BOULTER BOILERS is recommended (BS03052).

- Page 28 Fig. 4.12a Single Pipe Oil System. SINGLE PIPE OIL SYSTEM - OIL CONNECTIONS Items 1 - 5 supplied with Boiler Fig. 4.12b Schematic Oil Pipe Connectors CAMRAY 5 COMBI PAGE 20 TWO PIPE OIL SYSTEM - TANK OUTLET BELOW BURNER file://D:PL50000PL50000.htm 14/04/2005..

- Page 29 Page 29 of 77 Fig. 4.12c Two Pipe Oil System. TWO PIPE OIL SYSTEM - OIL CONNECTIONS Fig. 4.12d Schematic Oil Pipe Connectors CAMRAY 5 COMBI PAGE 21 DEAERATOR OIL SYSTEM - TANK OUTLET BELOW BURNER file://D:PL50000PL50000.htm 14/04/2005..

- Page 30 Fig. 4.12e Deaerator Oil Systems DEAERATOR PIPE OIL SYSTEM - OIL CONNECTIONS Fig. 4.12f Schematic Oil Pipe Connections. CAMRAY 5 COMBI PAGE 22 4:13 OIL BURNER The Burner makers technical leaflet is supplied with this manual and provides supplementary information not included in this manual.

- Page 31 Fig. 4.13b. Fig. 4.13b Burner Pump for Single Pipe Operation CAMRAY 5 COMBI PAGE 23 4:14 CONTROL PANEL The Control Panel is pre-wired and fitted to the Boiler ready for connection to the system wiring. For operation of the Control Panel see section 1 -User Guide.

- Page 32 BLUE = DHW 95 C Stat ORANGE = Control Stat WHITE = PRV Gauge RED = 110 C Limit Stat YELLOW = Tank Stat Fig. 4.14 Thermostat Phial Pocket positions CAMRAY 5 COMBI PAGE 24 4:15 FUNCTIONAL FLOW DIAGRAMS file://D:PL50000PL50000.htm 14/04/2005..

- Page 33 Page 33 of 77 CAMRAY 5 COMBI PAGE 25 file://D:PL50000PL50000.htm 14/04/2005..

- Page 34 Page 34 of 77 CAMRAY 5 COMBI PAGE 26 4:16 FITTING PROGRAMMER IMPORTANT The Electrical Installation of the programmer must be carried out by a suitably qualified electrical engineer / installer 1. Isolate Mains supply to boiler. 2. Remove Control Panel Cover.

- Page 35 4:17 PROGRAMMER INSTRUCTIONS 4:17.1 INTRODUCTION The Boulter Programmer is available in kit form as an optional extra for Boulter Buderus. Fitting Instructions for the programmer are included in the Programmer Kit. The Timer/Programmer is supplied pre-programmed with a ‘Standard’ set of times. These may be as required but can be easily changed if not.

- Page 36 Page 36 of 77 4:17.3 DAY TO DAY USE OF THE PROGRAMMER The Programmer has 6 options to select for CH and HW, these are printed on the unit and the arrow on the display points to the option when selected using the SELECT button. Off all the time TIMED On for three periods each day..

- Page 37 4. The first switching time ON1 must be set after 12:00am (Mid-night). 5. The last switching time OFF3 can be set after 12:00am (Mid-night). 6. The longest time from ON1>OFF3 is 23hrs 50mins. CAMRAY 5 COMBI PAGE 28 4:17.6 PROGRAMMES MON - FRI SAT &..

- Page 38 Page 38 of 77 FIRST ON 1 6:30am 6:30am 7.00am 7.00am PERIOD 8:30am 8:30am 9.00am 9.00am OFF 1 SECOND PERIOD ON 2 12 noon 12 noon 12 noon 12 noon OFF 2 12 noon 12 noon 12 noon 12 noon 4:30pm 4:30pm 4.00pm..

- Page 39 4:17.9 TEST The Test facility is a unique feature of the Boulter Programmer. Test enables a quick review of the 7 day programme. TO USE ‘TEST’ With the Timer/Programmer in the operating mode and the Display showing the correct Time and Day.

- Page 40 1. The terminals of balanced flues which can be touched are to be fitted with a guard. Any proposed installation which deviates from the details provided or gives rise to any doubt should be referred to BOULTER BUDERUS LTD. who will be pleased to consider and discuss it. 5:1.1 Balanced Flue Types Three types are available 1.

- Page 41 (see BS5410:1). 3. Care should be taken to ensure that there is clearance between the outer surface of the flue and any combustible material. CAMRAY 5 COMBI PAGE 30 5:4 POSITIONING THE BOILER Read Sections 5:2 &5:3..

- Page 42 BOULTER BUDERUS would be pleased to advise on any difficult positioning Fig. 5.4 Balanced Flue Terminal Positions CAMRAY 5 COMBI PAGE 31..

- Page 43 Page 43 of 77 Generally, exhaust 2 metres above ground level alleviates the necessity for a guard. A suitable guard is available from BOULTER BUDERUS as shown below. Fig. 5.5 5:6 HORIZONTAL FLUE TERMINAL The Terminal for Horizontal Balanced Flue is secured to the wall by means of four screws. The indexing plate should have its four edges siliconed to the outside wall to provide a weather seal.

- Page 44 3. Ensure that the outlet of the Terminal points downward (TOP upper-most and Boulter correct way up). 4. Ensure that the boiler to offtake gasket is fitted (foil face upwards) and the clamp is made with four nuts and washers securely fixed.

- Page 45 Page 45 of 77 that it is not damaged and that either end is connected via the jubilee clip provided to ensure correct boiler operation. CAMRAY 5 COMBI PAGE 33 6:2 LOW LEVEL HORIZONTAL FLUE 6:2.1 Rear Fig. 6.2a Low Level Horizontal Rear 6:2.2 Side - Left hand only..

- Page 46 Page 46 of 77 6:2.3 Low Level Assembly LOW LEVEL FLUE INSTALLATION Site conditions will dictate to a certain extent the best method of assembling low level balanced flues. The illustration shows a typical rear outlet flue. Assemble the flue generally as follows: 1.

- Page 47 Boulter is upright. 15.Secure the terminal to the flange using the four screws. 16.Fit an approved terminal guard if in an accessible position. Available from Boulter Buderus. 17.Inside: Using the clips supplied fix the flexible air duct to the burner spigot and flue offtake securely.

- Page 48 Page 48 of 77 Fig. 6.3a High Level Horizontal Rear CAMRAY 5 COMBI PAGE 36 file://D:PL50000PL50000.htm 14/04/2005..

- Page 49 Page 49 of 77 Fig. 6.3b Low Level Horizontal Flue Assembly HIGH LEVEL SIDE & REAR INSTALLATION Assemble the flue generally as follows: 1. Position boiler check that all water connections and proposed flue position are according to clearances specified. 2.

- Page 50 18. Taking the terminal end, keeping it square to the external flange push home over the internal flue exhaust pipe until the four holes on the flange align. NB. Ensure that TOP is on the upper-most surface of the terminal and BOULTER is upright. 19.Secure the terminal to the flange using the four screws.

- Page 51 This is attained by pushing two telescopic flues together until the desired dimension is obtained. Secure any vertical lengths by using a drill and 4 self tapping screws supplied. CAMRAY 5 COMBI PAGE 38 6:4 VERTICAL FLUE FLAT ROOF INSTALLATION file://D:PL50000PL50000.htm..

- Page 52 Page 52 of 77 Fig. 6:4a Vertical Flue - Flat Roof CAMRAY 5 COMBI PAGE 39 6:4 VERTICAL FLUE FLAT ROOF INSTALLATION - CONTINUED 6:4.1 Notes on installation Site conditions will dictate the best method of assembling the Vertical Balanced Flue.

- Page 53 Page 53 of 77 IMPORTANT WARNING Where a flue system passes through a joist frame, it is essential that the integrity of the ceilings fire barrier is retained. This can be achieved by ALWAYS using the support plate and firestop ceiling trim. We would also recommend strongly the use of the Adjustable Joist Sleeve (optional) to complete the fire stop.

- Page 54 Continue with the rest of the installation. NOTE: Ensure that there is a minimum of a 50mm overlap at all telescopic flue joints CAMRAY 5 COMBI PAGE 40 Fig. 6:4b Vertical Flue - Flat Roof Assembly CAMRAY 5 COMBI PAGE 41 file://D:PL50000PL50000.htm..

- Page 55 Page 55 of 77 6:5 VERTICAL FLUE PITCH ROOF INSTALLATION Fig. 6:5a Vertical Flue - Pitched Roof CAMRAY 5 COMBI PAGE 42 6:5 VERTICAL FLUE PITCHED ROOF INSTALLATION - CONTINUED 6:5.1 Notes on installation Site conditions will dictate the best method of assembling the Vertical Balanced Flue.

- Page 56 Page 56 of 77 IMPORTANT WARNING Where a flue system passes through a joist frame, it is essential that the integrity of the ceilings fire barrier is retained. This can be achieved by ALWAYS using the support plate and firestop ceiling trim. We would also recommend strongly the use of the Adjustable Joist Sleeve (optional) to complete the fire stop.

- Page 57 21. Using the clips supplied fix the air duct to the burner spigot and vertical flue offtake spigot. Continue with the rest of the installation. NOTE: Ensure that there is a minimum of a 50mm overlap at all telescopic flue joints CAMRAY 5 COMBI PAGE 43 Minimum overlap of telescopic flues 50mm. file://D:PL50000PL50000.htm..

- Page 58 It is essential in the interest of boiler efficiency and reliable performance that once the Boiler has been installed it is first commissioned by a qualified engineer. If an engineer is not known Boulter will be pleased to provide details of a commissioning and servicing engineer from their register.

- Page 59 Page 59 of 77 7:2 RESPONSIBILITY It is the responsibility of the installer to ensure that the boiler is properly commissioned. It is essential that the commissioning procedures detailed in this manual are carried out preferably by a qualified OFTEC engineer using recognised test equipment.

- Page 60 BS 7074 Part 1 for information on sizing of the additional expansion vessel. CAMRAY 5 COMBI PAGE 45 7:8 BOULTER RECOMMENDED COMMISSIONING CHECKLIST - SHEET 1 OF 2 Tick off each item OIL TANK Is there sufficient oil, and of the correct grade for the appliance? Is the tank adequately supported? Is a damp-proof membrane inserted between the tank and support? (Non plastic tanks).

- Page 61 Page 61 of 77 Outer valve Filter Sludge cock (Non plastic tanks). HEIGHT OF TANK Is the bottom of the tank above the oil pump if a single pipe system is installed? OIL SUPPLY LINE Ensure that galvanised iron has not been used. If black iron has been used, is it protected against corrosion? Ensure that soldered connections on copper pipes have not been used.

- Page 62 Is the boiler flueway inspection cover screwed down sufficiently firmly to form a seal? Is the flexible air duct connected correctly. CAMRAY 5 COMBI PAGE 46 7:8 BOULTER RECOMMENDED COMMISSIONING CHECK LIST- SHEET 2 OF 2 CASING PANELS Have grommets been fitted to relevant oil supply entry points (knockouts)?

- Page 63 Page 63 of 77 Has the chimney been adequately lined and insulated? NOTE:- Lining the flue and back filling will help prevent condensate problems BALANCED FLUE APPLIANCES Is the correct flue kit fitted? Is the Flue off take correctly secured to the boiler by four nuts and washers. Is the gasket provided fitted correctly? Has the rear Air Entry Plate been fitted with Blanking Plates where necessary? Can leakage from flues tubes or air ducts occur? All seals fitted correctly?

- Page 64 Is there sufficient system pressure? Record initial system pressure cold. Has a chemical dosing type water conditioner been fitted to the water supply to the boiler? CAMRAY 5 COMBI PAGE 47 7:9 BOULTER BUDERUS RECOMMENDED COMMISSIONING TESTS Have the manufacturers on-site assembly instructions been followed? 7:9.1 COMMISSIONING TESTS - BOILER..

- Page 65 Check the operation of the limit thermostat Complete commissioning report and enter the details on to the guarantee form which should be returned to BOULTER BOILERS in the envelope provided. Instruct the user on the operation of the appliance and leave this manual with the customer.

- Page 66 Allow boiler and tank to reach temperature again and switch to winter mode, adjust boiler control thermostat to maximum and repeat the last instruction. Continue with normal system checks. CAMRAY 5 COMBI PAGE 49 8:1 MAINTENANCE A boiler fired with Class C Oil should only require attentions once each year.

- Page 67 Page 67 of 77 assembly. CHANGE the nozzle for one with the specified make, oil rate, spray pattern and angle. Inspect the ignition electrodes for crazing in the porcelain. Replace if there are signs of deterioration. A dirty fan impeller can impair the performance of a burner, inspect and clean if necessary. Inspect photocell, if badly discoloured, change it.

- Page 68 Page 68 of 77 Complete a maintenance report and give the customer a copy, retaining a copy for your records. CAMRAY 5 COMBI PAGE 50 8:2 AIR SHUTTER ADJUSTMENT The Burner has a fixed Air Shutter with manual adjustment. To adjust the CO2 at the Air Shutter use a 3mm allen key as shown. To increase the setting turn the airshutter clockwise and to decrease turn anticlockwise.

- Page 69 Page 69 of 77 Fig. 8.3a Baffle Arrangement CAMRAY 5 COMBI PAGE 51 8:4 HEATING SYSTEM During routine servicing, the system water should be topped up if necessary, using the Filling Loop when the system is cold. Refer to 7:5 Filling the System.

- Page 70 Should be checked to be in accordance with the cold design pressure of the system. The design of the Camray 5 COMBI enables the Pressure Vessel to be lifted and laid on to the floor whilst still connected to the Boiler, enabling full access to the Burner and Heat Exchanger.

- Page 71 Replace control box. electric cell circuit faulty Flame instability Check combustion setting out and reset if necessary. CAMRAY 5 COMBI PAGE 58 Burner starts but will not This can be due either to light up absence of oil ignition. Oil pump air locked (repeat..

- Page 72 Checked and replace with correct size and type nozzle (see Technical Data) Air supply inadequate Check fan operation and cleanliness. CAMRAY 5 COMBI PAGE 59 Burner pulsates Worn nozzle with excess Replace with nozzle of correct type and size (a) continuously throughout or uneven..

- Page 73 High flue gas temperature Check: air shutter, nozzle size (see Technical Data), clean heat exchanger surfaces. Oil odour Leaking joints Break all leaking joints and re-make CAMRAY 5 COMBI PAGE 60 High operating Control stat failed and Replace control stat and reset Limit Thermostat temperature operating on limit stat..

- Page 74 Bleed air from pipe and repressurise if required CAMRAY 5 COMBI PAGE 62 10:4 FAULT FINDING SYSTEM WINTER MODE (DHW & CH) SYMPTOM FAULT REMEDY..

- Page 75 Free off or replace circulating pump. thermostat is tripped, no heat to tank or heating CAMRAY 5 COMBI PAGE 63 10:5 PARTS REPLACEMENT INSTRUCTIONS Note: Before attempting any parts replacement ALWAYS isolate appliance from mains electricity supply. 10:5. 1) To remove/replace circulating pump:..

- Page 76 Remove cable grip and ease cable from control panel e) Reassemble in reverse order, reinstate cold mains supply and test correct functioning of flow switch. CAMRAY 5 COMBI PAGE 65 11 INSTRUCTIONS FOR CONNECTING AN EXTERNAL PROGRAMMER 1) These instructions are ONLY for suitably qualified personnel.

- Page 77 Boulter Boderus Limited, Magnet House, 30 White House Road, Ipswich IP1 5JA Tel:01473 241555 Fax:01473 241321 Boulter Boderus policy is one of continuous research and development and this may necessitate alterations to this specification from time to time. Boulter Boderus reserve the right to do this without prior notification.

- Quick Links:

Oil Boiler Ireland

Related Manuals for Boulter Camray 5

Oil Boiler Oil-fired Boilers

Summary of Contents for Boulter Camray 5

Oil Boiler Troubleshooting

- Page 1 Page 1 of 67 Installation & Maintenance Manual For Camray 5 and Camray Utility 5 Oil Fired Boilers Manual Part No. PL 47000 Issue No. 4 Date of Issue: November 2001 file://D:PL47000PL47000.htm 14/04/2005..

- Page 2 Page 2 of 67 HEALTH AND SAFETY INFORMATION FOR THE INSTALLER AND SERVICE ENGINEER. Under the Consumer Protection Act 1987 and the Health and Safety at Work Act 1974, it is a requirement to provide information on substances hazardous to health (COSHH Regulations 1988). The Company takes every reasonable care to ensure that these products are designed and constructed to meet these general safety requirements, when properly used and installed.

- Page 3 7. Under no circumstances should mineral oils be taken internally. OFTEC Code of Practice OCP/1: 1995 For the Safe Installation, Commissioning, Maintenance and Fault Rectification of Oil Firing Equipment should be consulted. BOULTER BOILERS Boulter Boilers Limited Magnet House, White House Road, Ipswich IP1 5JA..

- Page 4 Page 4 of 67 1:5:7 Shutting Off for Summer 1:5:8 Sealed System Central Heating 1:5:9 Frost Protection 1:5:10 Oil Delivery 1:5:11 Maintenance/Troubleshooting Guide 1:5:12 Option Programmer SECTION 2 - INTRODUCTION 2:1 Introduction 2:2 Flue Options 2:3 Commissioning 2:4 Safety SECTION 3 - TECHNICAL DATA 3:1 Fuels 3:2 Boiler Technical Details 3:3 Burner Details..

- Page 5 BOULTER BUDERUS CAMRAY 5 PAGE 1 1:1 INTRODUCTION Getting to Know your New Camray 5 Boiler Thank you for choosing the Camray 5 -manufactured in the UK by Boulter Buderus who are renowned oil-firing specialists. Before using your new Boiler, we ask that you carefully read the following information.

- Page 6 Boiler has been installed it is first commissioned by a competent and preferably an O.F.T.E.C.* registered engineer. It is the responsibility of the installer to ensure that the Boiler is commissioned. If an engineer is not known, Boulter Buderus will be pleased to provide details of commissioning and servicing engineers from their register.

- Page 7 Page 7 of 67 1:4 BOILER CONTROL PANEL Boiler Control Panel (see fig 1. Boiler Control Thermostat Switch/Mains On Switch. 2. Boiler Overheat/Limit Thermostat Reset Button. 3. ‘Lockout’ Indicator- RED. }These will not be lit until activated 4. Mains Indicator- ORANGE }These will not be lit until activated 5.

- Page 8 Control Panel Arrangement BOULTER BUDERUS CAMRAY 5 PAGE 3 1:5.4 LOCKOUT INDICATOR (Camray 5 Kitchen Model Only) In the unlikely event of a Burner malfunction, it will automatically shutdown, and the red lockout indicator on the Control Panel will be lit.

- Page 9 1:5.8 SEALED SYSTEM CENTRAL HEATING If your Camray 5 or UTlLlTY Boiler is used on a SEALED SYSTEM, it is important that the correct operating system pressure is maintained. Your Installer should give guidance on this.

- Page 10 Flue Terminal Pluming Due to the high efficiency of the Camray 5 range white water vapour from the flue discharge - called pluming may be observed from time to time under certain weather conditions. This is perfectly normal and should be no cause for concern.

- Page 11 All models are supplied as standard with low level horizontal firing Oil Burner, they are suitable for connection to a conventional chimney or any of the Camray 5/Utility Balanced Flue options. Note: The nozzle on this appliance is only covered by a 1 year guarantee.

- Page 12 BOULTER BUDERUS CAMRAY 5 PAGE 6 3:1 LIQUID FUELS The Camray 5 and Camray 5 UTILITY Boilers will burn liquid fuels complying with BS2869 Part 2 1988 Class C2 as specified in the Code of Practice for Oil Firing BS5410 Part 1.

- Page 13 This appliance must be effectively earthed and connection to the supply must be through a double pole isolating switch fused 5 amp. The isolating switch must have all pole contact separations at least 3mm BOULTER BUDERUS CAMRAY 5 PAGE 7 3:5 DIMENSIONS Output..

- Page 14 Page 14 of 67 BOULTER BUDERUS CAMRAY 5 PAGE 8 3:6 COMMISSIONING DATA 3:6.1 Class C2, Kerosene Oil RIELLO BURNER Model Output Riello Nozzle Pump Fuel C02% Smoke Flue Exit Boiler Test Camray5 R D B Danfoss Pressure Rate Point Temp Temp Utility &..

- Page 15 91%) Heat Output (Full Load) kW 26.4 38.1 BOULTER BUDERUS CAMRAY 5 PAGE 9 4:1 STANDARDS & REGULATIONS The installation of the Boiler must comply with the latest edition of : BS 5410 Oil Installations Pt 1 up to 44kW;..

- Page 16 6. Any kitchen work top above the 100/130 Boiler must be removable for service access. 4:4 THE HEARTH The Camray 5 & Camray 5 Utility have a Hearth Temperature of less than 85°C. The boiler requires a level hearth on which to stand which should comply with the Building Regulations.

- Page 17 Page 17 of 67 The boiler requires a minimum stable draught of 0.1 mbar (0.04w.g.). If the chimney exceeds 6m (20 feet) in length, it may produce a draught exceeding 0.37 mbar (0.15' w.g.) and a draught stabiliser should be fitted. The chimney should comply with the latest edition of the Building Regulations and BS 5410: Part 1.

- Page 18 When the Boiler is installed in a basement or low level boiler house where air can enter only from high level, the incoming air supply for Combustion and Ventilation should be ducted to low level. A high level outlet should be provided for ventilation. BOULTER BUDERUS CAMRAY 5 PAGE 11 4:7 OIL STORAGE 4:7.1 Oil Tank Consideration to the access by fuel delivery lorries should be given when positioning the oil tank.

- Page 19 50mm thick garden slabs or a concrete base. As there is only one tapped outlet they are more suited to single pipe feed as gravity supply or with a Boulter 3K Oil Loop Deaerator where suction lift is required.

- Page 20 4:8.7 Flexible Oil Pipes Camray 5 Boilers and 3K Deaerator Fitting Kits are supplied with long life Flexible Oil Pipes. The Flexible Oil Pipes are fitted inside the Boiler casing and are of adequate length to enable the Burner to be removed without disconnecting.

- Page 21 Page 21 of 67 Flexible Oil Pipes and Fire Check Valve BOULTER BUDERUS CAMRAY 5 PAGE 13 file://D:PL47000PL47000.htm 14/04/2005..

- Page 22 Page 22 of 67 BOULTER BUDERUS CAMRAY 5 PAGE 14 file://D:PL47000PL47000.htm 14/04/2005..

- Page 23 Page 23 of 67 BOULTER BUDERUS CAMRAY 5 PAGE 15 file://D:PL47000PL47000.htm 14/04/2005..

- Page 24 Page 24 of 67 BOULTER BUDERUS CAMRAY 5 PAGE 16 4:9 OIL BURNER The Burner makers’ technical leaflet is supplied with this manual and provides supplementary information not included in this manual. 4:9.1 Burner Pump for Two Pipe and Deaerator System For two pipe oil systems the Burner Oil Pump has to be fitted with the Bypass Screw supplied.

- Page 25 The Control Panel is pre-wired and fitted to the Boiler ready for connection to the system wiring. 4:10.1 Connecting Control Panel If a Boulter Programmer is to be fitted refer to section 4:11 of this manual for fitting instructions before connecting mains.

- Page 26 Page 26 of 67 2. Insert Mains Plug into the mating Mains Socket on the underside of the Control Panel. 3. Insert 4 pin Burner Plug on the end of the Burner Cable into its mating Socket on the underside of the Control Panel.

- Page 27 Page 27 of 67 BOULTER BUDERUS CAMRAY 5 PAGE 18 4:11 PROGRAMMER - CAMRAY 5 ONLY IMPORTANT The Electrical Installation of the programmer must be carried out by a suitably qualified electrical engineer/installer The Programmer kit is available as an optional extra. ( FOR THE WHITE CASED KITCHEN MODEL ONLY) The unit is supplied pre-wired to a 12-way Terminal block as detailed in the wiring diagram and is available as Kit Part No.

- Page 28 Page 28 of 67 4. Remove the plate and carefully cut through the overlay with a sharp knife. 5. Feed the pre-wired terminal block and wires through the hole now exposed in the Control Panel. Click the Programmer in place from the front. 6.

- Page 29 PROGRAMMER INSTRUCTIONS 4:11.1 INTRODUCTION The Boulter Programmer is available in kit form as an optional extra for Boulter Buderus. Fitting Instructions for the programmer are included in the Programmer Kit. The Timer/Programmer is supplied pre-programmed with a ‘Standard’ set of times. These may be as required but can be easily changed if not.

- Page 30 Page 30 of 67 4:11:4 SETTING THE CLOCK 1. Switch ON the Electrical Supply to the Boiler - the Clock Display should come on. 2. Press and release once. Display > 3. Press and release once to answer. The Day on the Display will flash. Display >..

- Page 31 4:30pm 4:30pm 4.00pm 4.00pm OFF 3 10:30pm 10:30pm 11.00pm 11.00pm BOULTER BUDERUS CAMRAY 5 PAGE 20 Pencil in your own programme below for reference CUSTOM PROGRAMME MON - FRI SAT & SUN PROGRAMME PROGRAMME FIRST PERIOD ON 1 OFF 1..

- Page 32 4:11.9 TEST The Test facility is a unique feature of the Boulter Programmer. Test enables a quick review of the 7 day programme. TO USE ‘TEST’ With the Timer/Programmer in the operating mode and the Display showing the correct Time and Day.

- Page 33 4:11.10 HOLIDAY The Holiday Setting is a unique feature of the Boulter Programmer. This enables a period of days to be set (up to 99) during which time the Heating System is OFF. When the Holiday Period is over the Programmer reverts back to the normal programme.

- Page 34 Page 34 of 67 BOULTER BUDERUS CAMRAY 5 PAGE 22 IMPORTANT ENSURE GOOD EARTH file://D:PL47000PL47000.htm 14/04/2005..

- Page 35 4:12.1 Typical External Wiring options IMPORTANT Blue tag must only be fitted to terminal 6 of time clock for gravity hot water only. It must be removed for fully pumped systems. BOULTER BUDERUS CAMRAY 5 PAGE 23 5:1 BALANCED FLUE BOILERS file://D:PL47000PL47000.htm..

- Page 36 Page 36 of 67 A range of Balanced Flue Kits are available as optional extras for Camray 5 & Utility. Balanced Flues permit considerable choice of siting of the Boiler. Boilers may be installed in situations where no chimney exists, where the chimney is unsatisfactory or in outhouses.

- Page 37 (see BS 5410:1). 3. Care should be taken to ensure that there is clearance between the outer surface of the flue and any combustible material. BOULTER BUDERUS CAMRAY 5 PAGE 24 5:4 POSITIONING THE BOILER Read Sections 5:2 &..

- Page 38 BOULTER BUDERUS would be pleased to advise on any difficult positioning Fig. 5.4a Balanced Flue Terminal Positions BOULTER BUDERUS CAMRAY 5 PAGE 25..

- Page 39 LOW LEVEL AND HIGH LEVEL BALANCED FLUES 1. The Terminal must be slightly angled down to ensure correct operation of the boiler. Due to the efficiency levels of Camray 5 pluming from the terminals may occur under certain conditions. Any condensation may be file://D:PL47000PL47000.htm..

- Page 40 3. Ensure that the outlet of the Terminal points downward (TOP upper-most and Boulter correct way up). 4. Ensure that the boiler to offtake gasket is fitted (foil face upwards) and the clamp is made with four nuts and washers securely fixed.

- Page 41 Page 41 of 67 BOULTER BUDERUS CAMRAY 5 PAGE 28 LOW LEVEL FLUE INSTALLATION Site conditions will dictate to a certain extent the best method of assembling low level balanced flues. The illustration shows a typical rear outlet flue. Assemble the flue generally as follows: 1.

- Page 42 ‘Boulter’ is upright. 15. Secure the terminal to the flange using the four screws. 16. Fit an approved terminal guard if in an accessible position. Available from Boulter Buderus. 17. Inside: Using the clips supplied fix the flexible air duct to the burner spigot and flue offtake securely.

- Page 43 Page 43 of 67 BOULTER BUDERUS CAMRAY 5 PAGE 30 file://D:PL47000PL47000.htm 14/04/2005..

- Page 44 Page 44 of 67 HIGH LEVEL SIDE & REAR INSTALLATION Assemble the flue generally as follows: 1. Position boiler check that all water connections and proposed flue position are according to clearances specified. 2. Mark the flue position on the wall. 3.

- Page 45 NB. Ensure that TOP is on the upper-most surface of the terminal and BOULTER is upright. 19. Secure the terminal to the flange using the four screws. 20. Fit an approved terminal guard if in accessible position.

- Page 46 Page 46 of 67 BOULTER BUDERUS CAMRAY 5 PAGE 32 6:4 VERTICAL FLUE FLAT ROOF INSTALLATION file://D:PL47000PL47000.htm 14/04/2005..

- Page 47 Page 47 of 67 BOULTER BUDERUS CAMRAY 5 PAGE 33 6:4 VERTICAL FLUE FLAT ROOF INSTALLATION - CONTINUED 6:4.1 Notes on installation file://D:PL47000PL47000.htm 14/04/2005..

- Page 48 Page 48 of 67 Site conditions will dictate the best method of assembling the Vertical Balanced Flue. The following illustrations show boilers up against a rear wall as an example. It is not essential for the boiler to be positioned this way; As long as the joists are capable of supporting the flue via the support plate supplied in the kit.

- Page 49 Keep Cravat as low as possible onto flashing plate to prevent entry of animals, birds or insects. 18. Inside: Using the clips supplied fix the air duct to the burner spigot and vertical flue offtake spigot. Continue with the rest of the installation. BOULTER BUDERUS CAMRAY 5 PAGE 34 file://D:PL47000PL47000.htm 14/04/2005..

- Page 50 Page 50 of 67 Fig. 6:4b Vertical Flue - Flat Roof Assembly BOULTER BUDERUS CAMRAY 5 PAGE 35 6:5 VERTICAL FLUE PITCHED ROOF INSTALLATION file://D:PL47000PL47000.htm 14/04/2005..

- Page 51 Page 51 of 67 BOULTER BOILERS CAMRAY 5 PAGE 36 6:5 VERTICAL FLUE PITCHED ROOF INSTALLATION - CONTINUED 6:5.1 Notes on installation file://D:PL47000PL47000.htm 14/04/2005..

- Page 52 Page 52 of 67 Site conditions will dictate the best method of assembling the Vertical Balanced Flue. The following illustrations show boilers up against a rear wall as an example. It is not essential for the boiler to be positioned this way. As long as the joists are capable of supporting the flue via the support plate supplied in the Kit or the Flue support quadrant kit (optional).

- Page 53 20. Drill the outer air ducts to secure extension to extension by 4 self tapping screws. 21. Using the clips supplied fix the air duct to the burner spigot and vertical flue offtake spigot. Continue with the rest of the installation. BOULTER BOILERS CAMRAY 5 PAGE 37 file://D:PL47000PL47000.htm 14/04/2005..

- Page 54 Page 54 of 67 Fig. 6:5b Vertical Flue - Pitched Roof Assembly BOULTER BUDERUS CAMRAY 5 PAGE 38 6:6 HIGH LEVEL FLUE LENGTH ALTERATION There is a certain amount of adjustment available on the vertical height and horizontal length. This is attained by pushing two telescopic flues together until the desired dimension is obtained. Secure any vertical lengths by using a drill and 4 self tapping screws supplied.

- Page 55 It is essential in the interest of boiler efficiency and reliable performance that once the boiler has been installed it is first commissioned by a competent engineer, preferably an OFTEC commissioning engineer. If an engineer is not known Boulter Boilers will be pleased to provide details of commissioning and servicing engineers from their register.

- Page 56 Page 56 of 67 Contents gauges Screw fill and indepentant vent cover or capped fill and vent pipes. Outer valve Filter Sludge cock (Non plastic tanks). HEIGHT OF TANK Is the bottom of the tank above the oil pump if a single pipe system is installed? OIL SUPPLY LINE Ensure that galvanised iron has not been used.

- Page 57 Is the boiler flueway inspection cover screwed down sufficiently firmly to form a seal? BOULTER BUDERUS CAMRAY 5 PAGE 41 7:4 BOULTER BUDERUS RECOMMENDED COMMISSIONING CHECK LIST - SHEET 2 OF 2 CASING PANELS Have grommets been fitted to relevant oil supply entry points (knockouts)?

- Page 58 Page 58 of 67 Is the flue adequately sized for the appliance rating? Is the flue free of any obstruction? Has the chimney been adequately lined and insulated? NOTE:- Lining the flue and back filling will help prevent condensate problems BALANCED FLUE APPLIANCES Is the correct flue kit fitted? Is the Flue off take correctly secured to the boiler by four nuts and washers.

- Page 59 Does the power supply cable enter the casing through a grommet? GENERAL Has the boiler been installed in accorandance with manufacturers instructions? BOULTER BUDERUS CAMRAY 5 PAGE 42 7:5 BOULTER BUDERUS RECOMMENDED COMMISSIONING TESTS Have the manufacturers on-site assembly instructions been followed?

- Page 60 Check the operation of the limit thermostat Complete commissioning report and enter the details on to the guarantee form which should be returned to BOULTER BOILERS in the envelope provided. Instruct the user on the operation of the appliance and leave this manual with the customer.

- Page 61 Page 61 of 67 Remove burner and clean thoroughly, the burner draught tube, the electrodes and generally the head assembly. CHANGE the nozzle for one with the specified make, oil rate, spray pattern and angle. Inspect the ignition electrodes for crazing in the porcelain. Replace if there are signs of deterioration. A dirty fan impeller can impair the performance of a burner, inspect and clean if necessary.

- Page 62 Page 62 of 67 BOULTER BUDERUS CAMRAY 5 PAGE 44 8:2 AIR SHUTTER ADJUSTMENT The Burner has a fixed Air Shutter with manual adjustment. To adjust the CO at the Air Shutter use a 3mm allen key as shown. To increase the setting turn the airshutter clockwise (+) and to decrease turn anticlockwise (-).

- Page 63 1. All baffles are horizontal 2. All baffle handles are in the forward position. BOULTER BUDERUS CAMRAY 5 PAGE 45 10:1 FAULT FINDING If the Boiler fails to start, make the following checks before calling a service engineer:- 1.

Page 64: Fault Finding Chart

Replace control box. electric cell circuit faulty Flame instability Check combustion setting out and reset if necessary. BOULTER BUDERUS CAMRAY 5 PAGE 53 Burner starts but will not This can be due either to light up absence of oil of ignition.- Page 65 Checked and replace with correct size and type nozzle (see Technical Data) Air supply inadequate Check fan operation and cleanliness. BOULTER BUDERUS CAMRAY 5 PAGE 54 Burner pulsates Worn nozzle with Replace with nozzle of correct type and size (see (a) continuously excess throughout or Technical Data).

- Page 66 Commissioning Check List and Servicing supply Notes. Due to a policy of continual development Boulter Buderus reserves the right to alter or amend the design of its products without prior notice. Indicates changes from previous issue BOULTER BUDERUS CAMRAY 5 PAGE 56 file://D:PL47000PL47000.htm..

- Page 67 Boulter Boilers Limited Magnet House 3 0 White House Road Ipswich IP1 5JA Tel: 01473 241555 Fax: 01473 241321 E-mail: sales@boulter-boilers.com Due to a policy of continual development Boulter Boilers reserves the right to alter or amend the design of its products without prior notlce file://D:PL47000PL47000.htm..